What is your sample or drill hole spacing? We are supposed to know in order to disclose exploration information and to estimate mineral resources, according to 43-101 and JORC guidelines. JORC code states: “Geological evidence and knowledge required for the estimation of Mineral Resources must include sampling data of a type, and at spacings, appropriate to the geological, chemical, physical, and mineralogical complexity of the mineral occurrence, for all classifications of Inferred, Indicated and Measured Mineral Resources.” Leaving the complete ambiguity of some of the language in that paragraph aside for now, what is clear is that we’re supposed to have some sort of standard so that we can judge whether the sample spacing is “appropriate”. For as many press releases and reports that I read, I can’t remember one that really quantified spacing in meaningful or accurate terms. (In Russia, you will be told what spacing to drill your deposit, so there’s no place for weasels there). Is it the planned spacing? Is it a rough average determined with the eyeball? Is there something better?

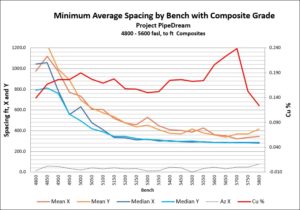

One way is to think of the hole spacing problem with reference to a long section or a bench plan, reducing it to a 2D assessment. We composite our data to the benches or sections and compute statistics to determine spacing between the bench, section, or vein composites. But is that all? Actually, the spacing varies by direction, so we need to determine the spacing along the orthogonal axes that return the minimum distance. You can graph the results of a spacing analysis, such as the sample below.

Drill Hole Spacing and Average Grade Displayed by Bench Interval

And what statistic should we use? The mean? Well, that depends on the drill pattern. The median is usually a much better measure of the drill spacing. The mean may return a significantly wider sample spacing than the median because the less economically important deposit limits are drilled or sampled at much wider spacing. But there’s more insight from the 2d analysis and a graph like the one above; e.g. we can note that sample spacing increase with depth, and that the best grade is drilled at the tightest spacing.

If you’re interested in what your sample spacing is and what it can tell you, send us a message on the Contacts page. HoleSpacer2D is a Visual Basic module that runs in Microsoft EXCEL.